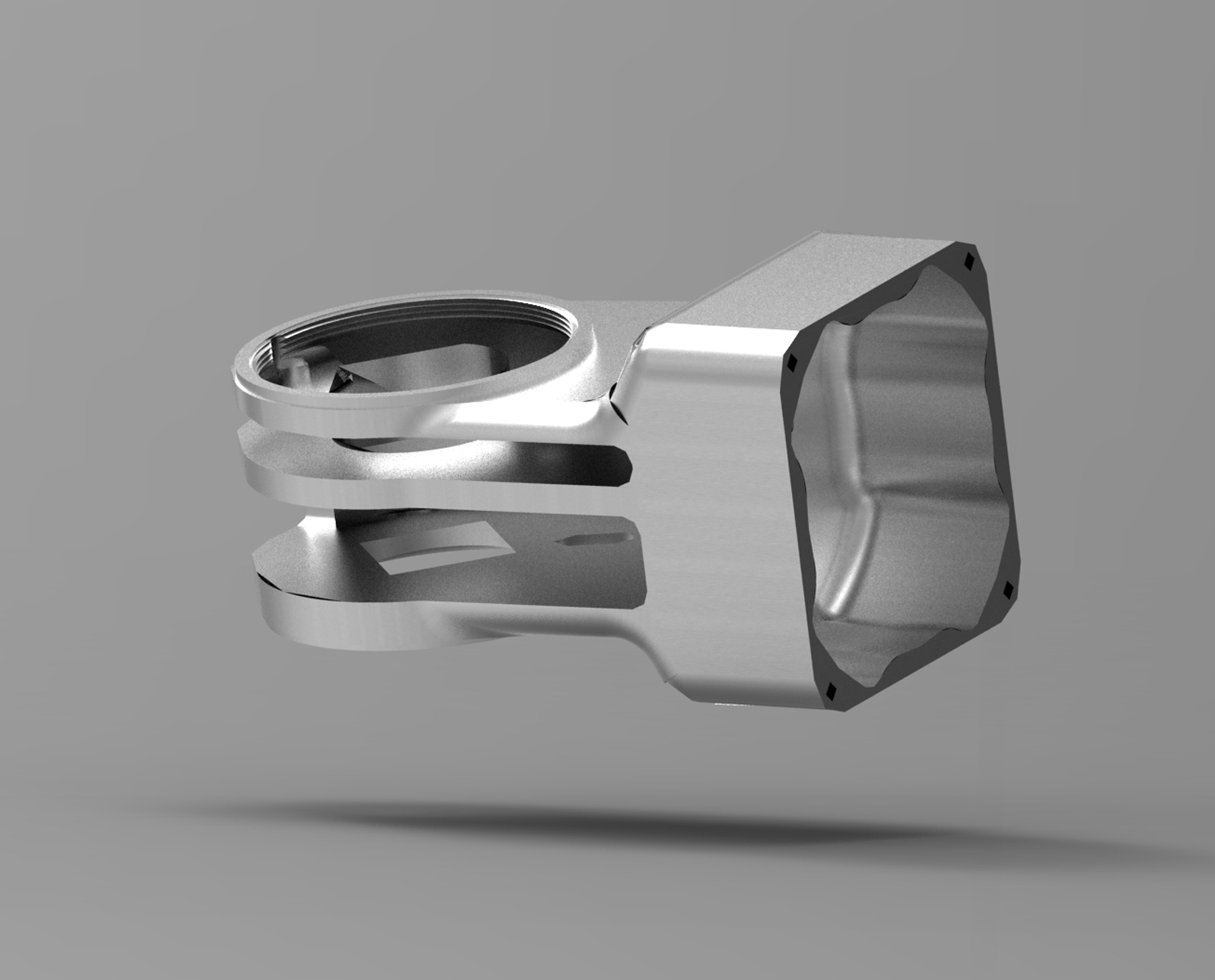

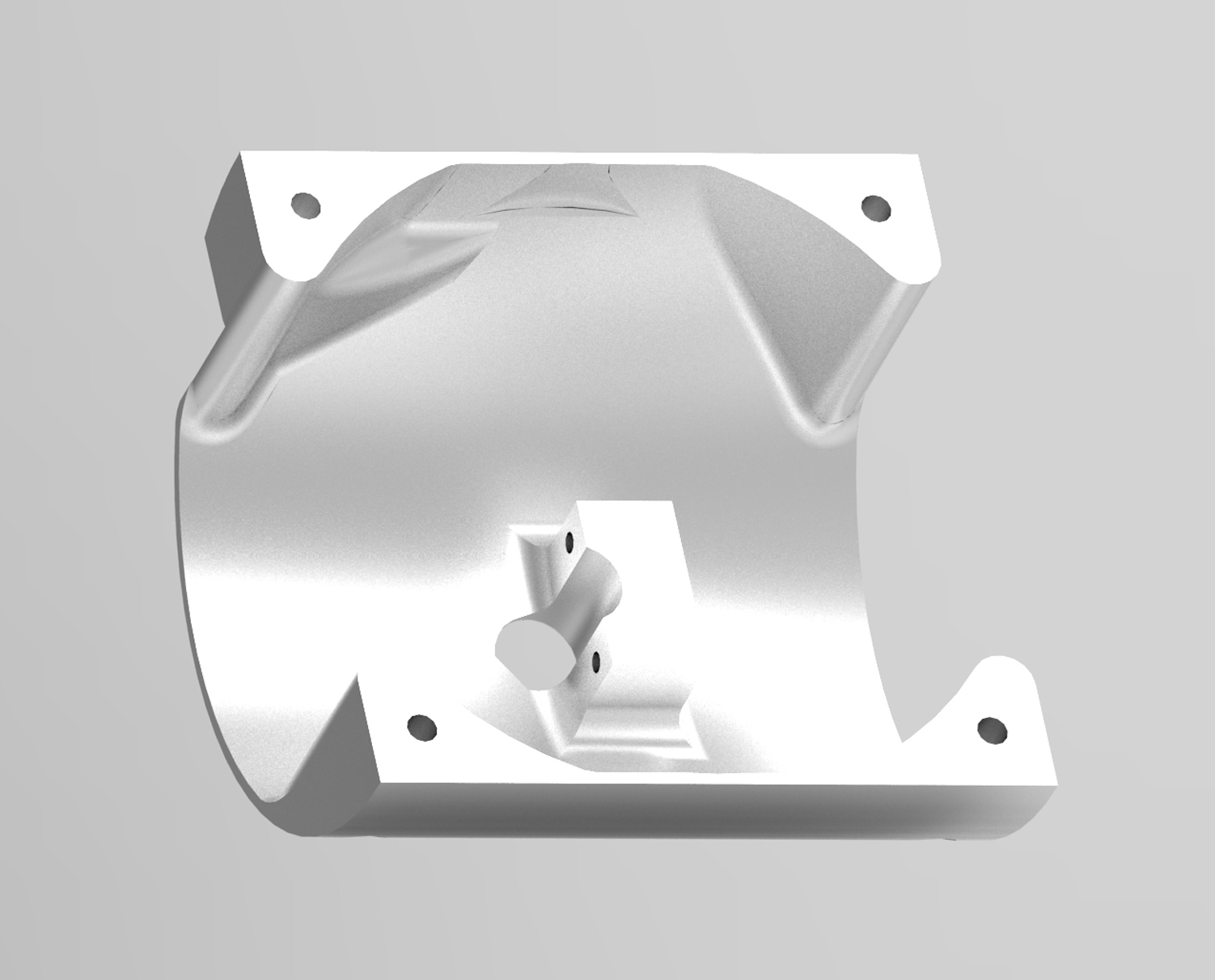

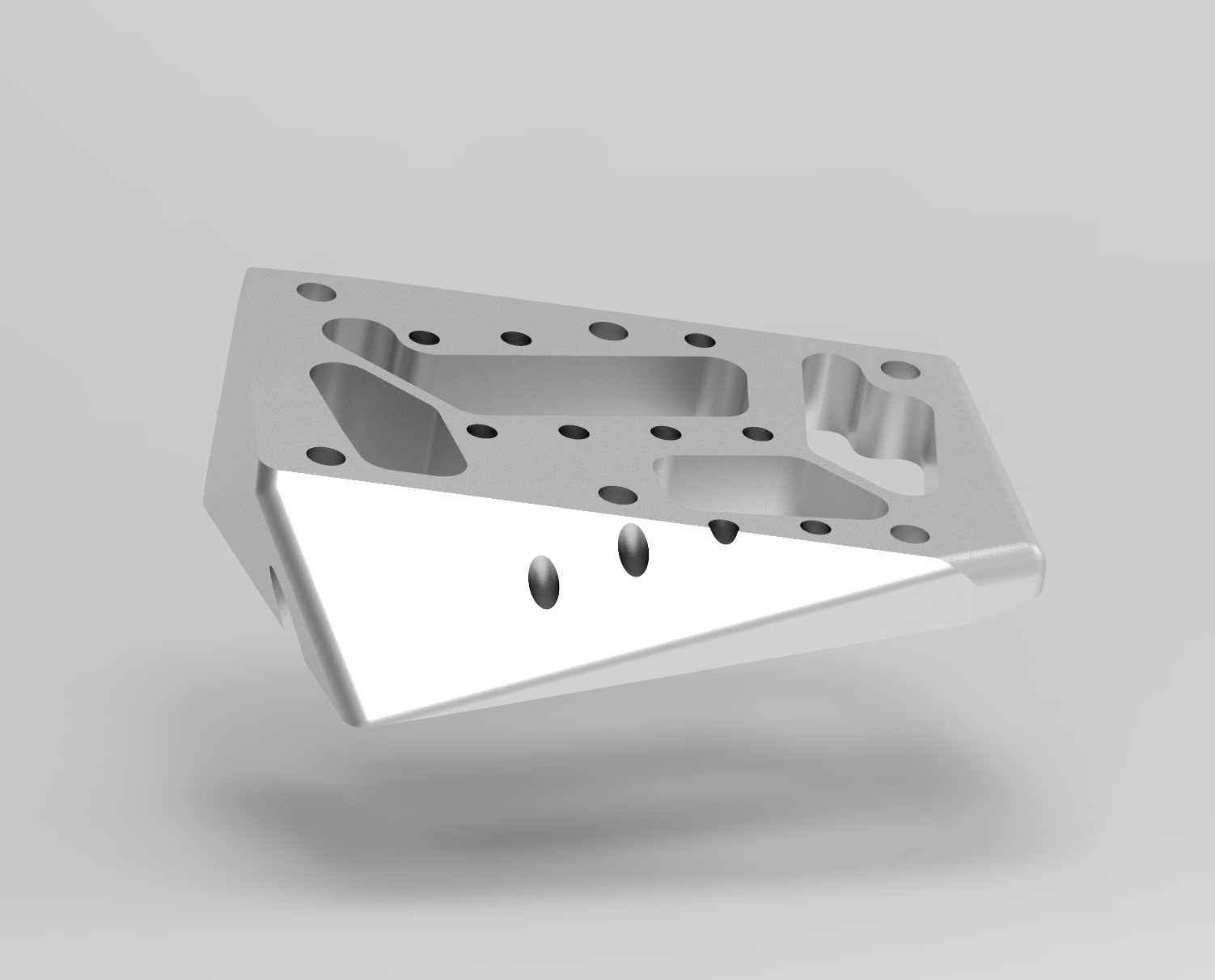

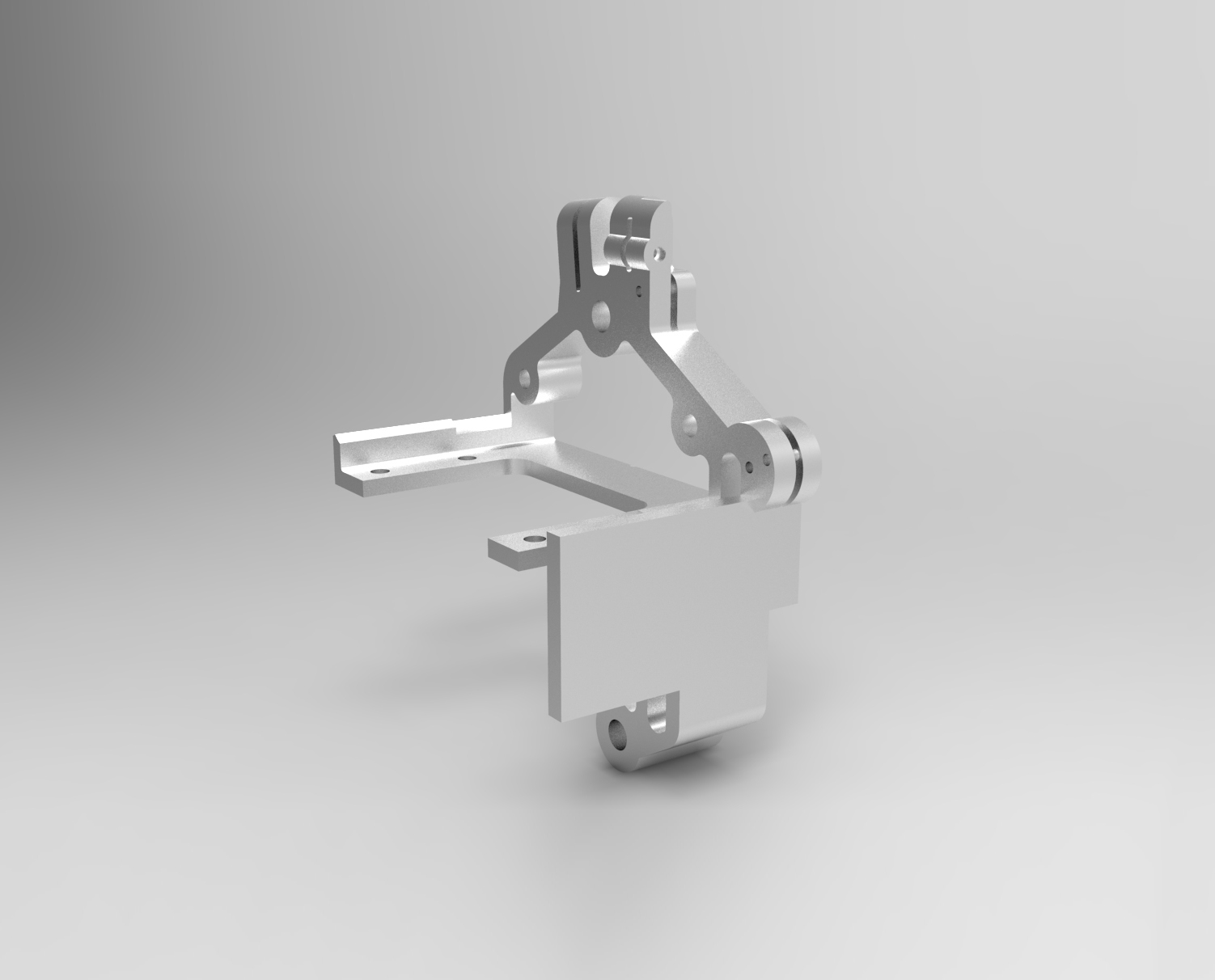

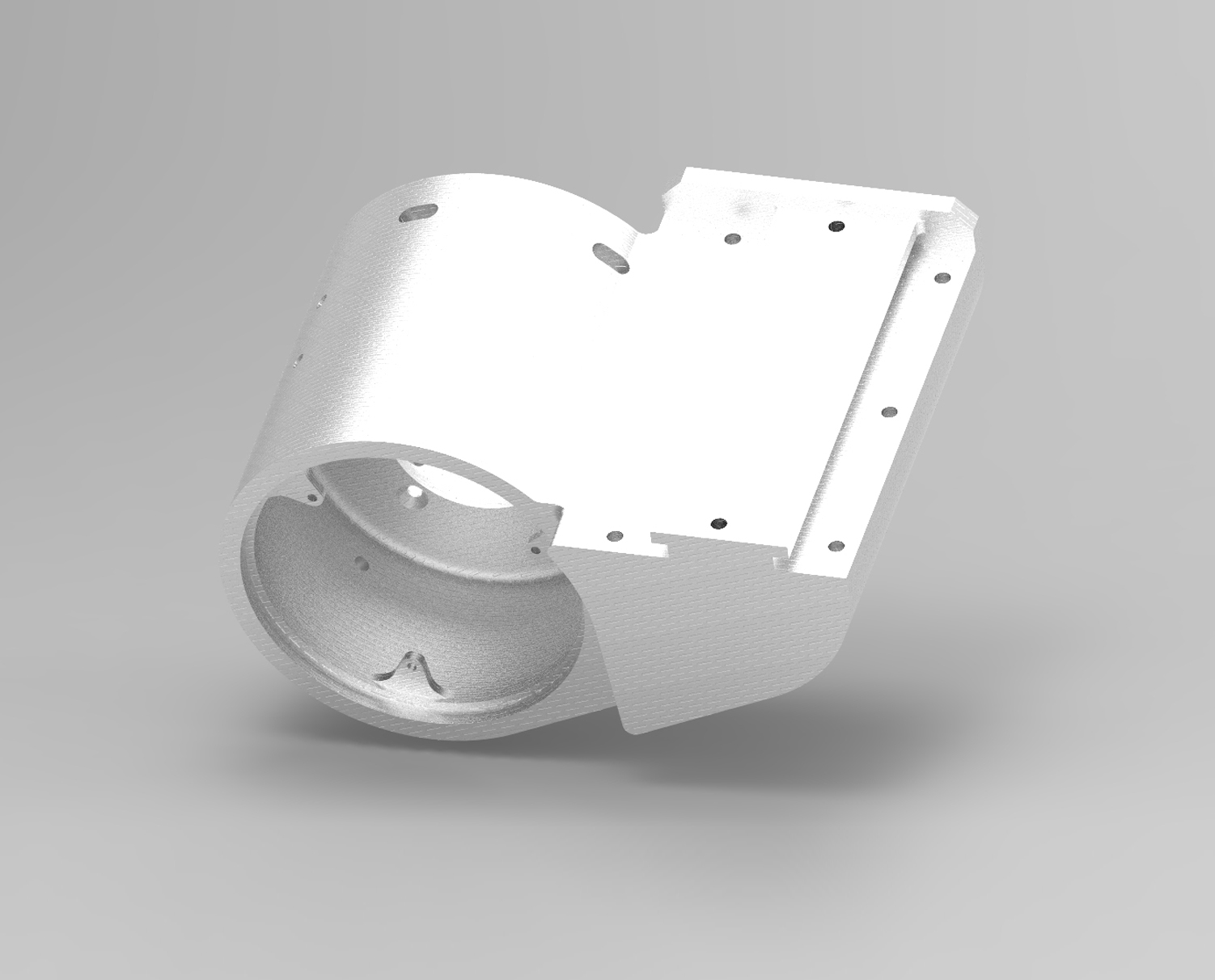

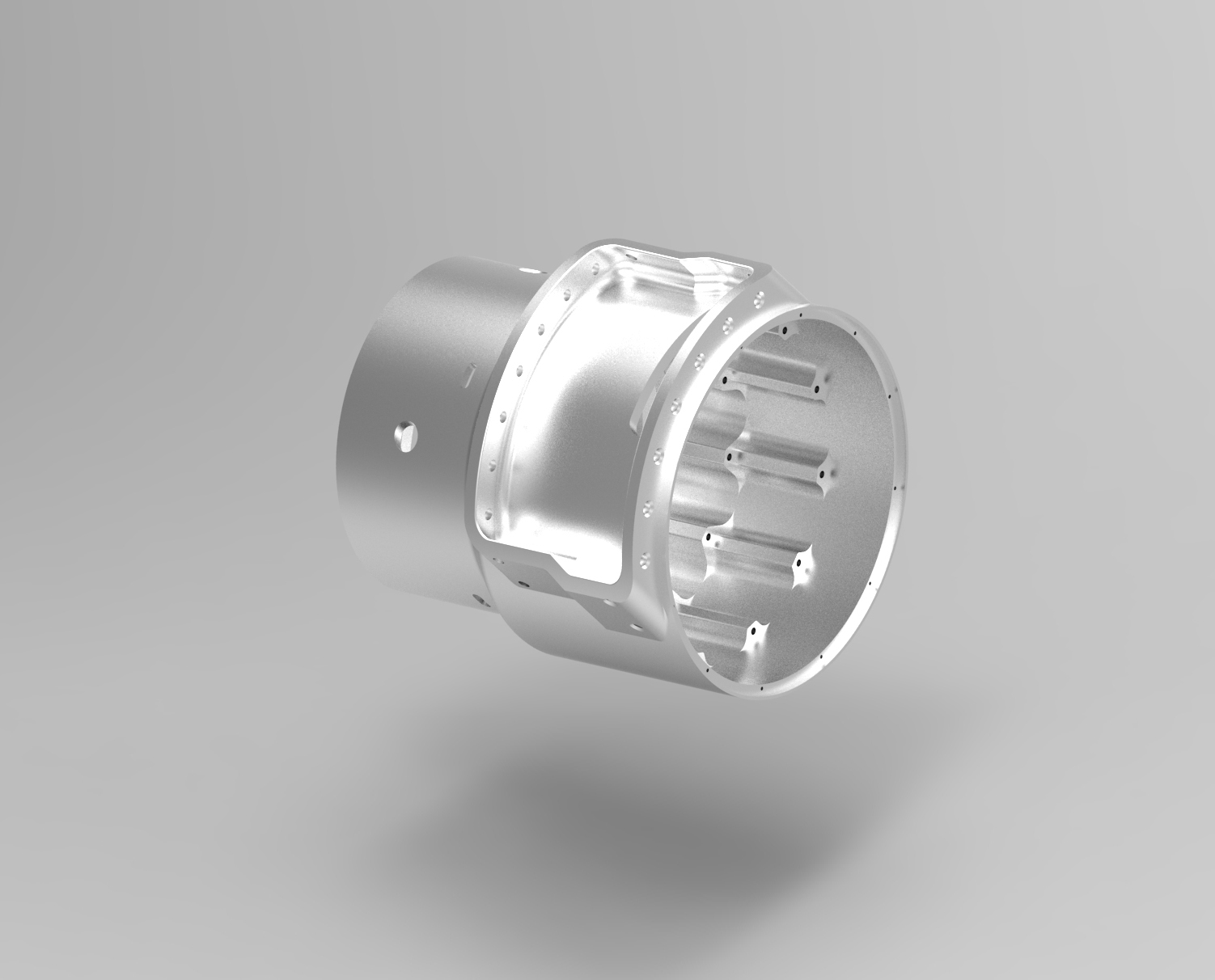

Machined Parts

Have any Questions? Call us Toll Free

888.207.0646

Brochures

PTEC Solutions Inc. is a trusted leader in the industry, with a proven track record of over 30 years providing top-notch support for a wide range of machine requirements. Located in the bustling hub of innovation in Silicon Valley, California, our team of experts is dedicated to meeting the needs of our clients, no matter how simple or complex.

From standard projects to highly customized solutions, we have the technical know-how and manufacturing capabilities to deliver exceptional results. Our commitment to quality, service, and value sets us apart from the competition, ensuring that our customers receive the best possible outcomes for their projects.

Whether you’re in need of prototyping services or require large-scale production, PTEC Solutions Inc. is here to help. No job is too small or too large for our team of dedicated professionals, who are ready to tackle any challenge with precision and expertise. Trust us to bring your vision to life and exceed your expectations every step of the way.

MACHINED & SHEET METAL PARTS

Industries Supported

⇒ Medical

⇒ Military

⇒ Telecommunications

⇒ Semi-Conductor

Equipment

⇒ Akira-Seiki CNC Vertical Machining Centers (16)

⇒ Akira-Seiki Turning Centers (2)

⇒ Akira-Seiki Horizontal (1)

⇒ Manual Lathe (2)

⇒ Manual Mill (2)

⇒ Mitutoyo Bright A504 Coordinate Measuring Machine

⇒ Miller Syncrowave 350LX

⇒ Miller 650SX Arc Station Welding

⇒ Multiple surface plates, height gage, micrometers, gage pins, thread gage, calipers, etc…and other necessary equipment required to perform quality control functions.

Services

⇒ Quick turn and custom services

⇒ NPI and proto‐type support

⇒ Small volume to high mix – high volume

⇒ Assist to Design engineering support

⇒ 15+ years of industry experience

⇒ AutoCad, Solid Works and OrCard Support

Production Capabilities

⇒ Proto-type and to production level support

⇒ Low and High volume

⇒ Kan-ban capabilities

⇒ Tolerances within .002”

⇒ Capability for parts as small as 0.500 Inches to 8 Feet in length.

⇒ Finish per Customer Requirements

Process

⇒ Our process includes inspection at every point on the production floor

⇒ First part inspection prior to production run

⇒ Verification for services provided by AVL

⇒ Final inspection and reports as required per customers specifications

⇒ Experience on the manufacturing of parts for more than 15 years.

Materials

⇒ Cold Roll Steel

⇒ Aluminum

⇒ Plastics

⇒ Materials from Customer requirements

⇒ Etc…

Sheet Metal Capabilities

⇒ Materials and Component Expertise

⇒ NPI and Production Capacities

⇒ Quick Turn Services Available

⇒ Competitive Pricing

⇒ Full BOM and Drawing Engineering Support

⇒ Full Turnkey and Consignment Support

⇒ Plating and Anodizing support

⇒ Standard and custom silkscreen services

Materials

⇒ Cold Roll Steel

⇒ Aluminum

⇒ Plastics

⇒ Materials from Customer requirements

⇒ Etc…

Specifications

⇒ Per Customer requirements

⇒ Military specifications

⇒ Medical

⇒ Industry Standards